Related News

Choose lithium battery for forklifts

There are increasing demands of advanced lithium battery for forklift industry recently, therefore we would suggest how to choose a right lithium battery for your forklifts!

Wide Application of Lithium Iron Phosphate Batteries in Forklifts

How much do you know about the application of lithium iron phosphate batteries in electric forklifts?

CeMAT Asia Exhibition at Pudong Shanghai

CeMAT Asia Exhibition will be hold from 1st to 4th Nov 2016 at Pudong Shanghai

Analysis of the current situation and future trends of lithium batteries in the forklift industry!

2023-10-31 | Power Battery - Electric Forklift

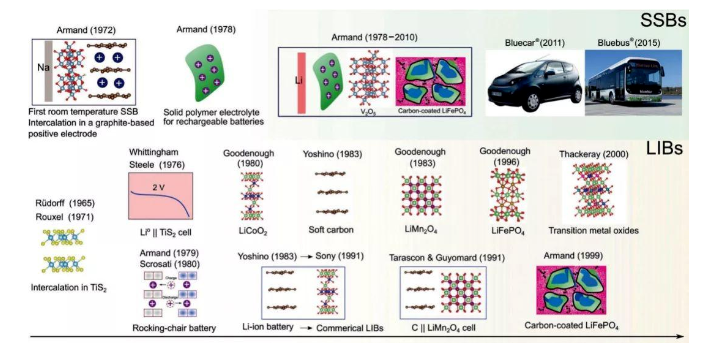

The origin and development of lithium batteries: The development of lithium batteries began in the 1970s, when Michel Armand first proposed the design concept of solid-state batteries. Later, he also proposed the concept of "rocking chair battery", which pointed the direction for the development of lithium-ion batteries (LIBs) and sodium-ion batteries (SIBs). In less than a decade, the composition and energy storage principles of lithium batteries were elucidated, representing an important breakthrough in the history of science.

Research focus in academia: Subsequently, the research focus in academia turned to how to improve battery performance by improving material systems. Lithium-ion batteries are leading the development, and a series of cathode materials, such as lithium cobalt oxide, lithium iron phosphate and ternary materials, have emerged to improve battery performance.

The development direction of lithium batteries: The original intention of lithium batteries is all-solid-state lithium metal batteries. Although this field is still making progress, it is not yet mature. Lithium-ion batteries remain the market-dominating technology, while all-solid-state lithium metal batteries have yet to reach the same commercial level. China-made lithium batteries have made important progress in the field of lithium-ion batteries.

This information highlights the importance of lithium batteries as an energy storage technology, as well as the rapid rise and continued efforts of Chinese-made lithium batteries in the lithium-ion battery field. The continuous development of lithium battery technology is of great significance for applications in electric vehicles, renewable energy storage and other fields.

In 1991, Sony commercialized lithium batteries, and in 1998, Panasonic mass-produced 18650 cylindrical lithium batteries for notebook computers. Compared with batteries that appeared earlier, such as fuel cells, lead-acid batteries, and nickel-cadmium batteries, lithium batteries have made mutual achievements with consumer electronics in the two decades since their birth due to their unparalleled advantages in weight, volume, and battery life. , and shine in the process of energy structure transformation. "They created a rechargeable world", three lithium battery leaders won the Nobel Prize in 2019, which was highly anticipated by everyone.

In the initial stage of the development of lithium batteries, China's advantage was manufacturing rather than R&D, so it was destined to participate in this world-changing journey as a follower. On the road to catch up, there are policies such as car purchase subsidies and battery whitelists to protect the company, and there is also "elegant help" such as BMW's 800 pages of technical standards for CATL.

The most important thing is that China's lithium battery industry continues to cultivate its internal strength. Engineer dividends have taken over the demographic dividend. From materials, equipment to battery manufacturing, every link is actively making progress.

By 2016, when the proportion of 3C batteries and power batteries in total shipments was close, the localization rate of the four main materials of positive electrode, negative electrode, electrolyte, and separator had reached about 90%. China's lithium battery industry Chain has completed most of the tasks of domestic replacement in the consumer battery era.

In 2011, CATL authorized Hyundai Mobis to use CTP (High Efficiency Packing) technology to export battery technology to South Korea, one of the former highlands, with different offensive and defensive trends.

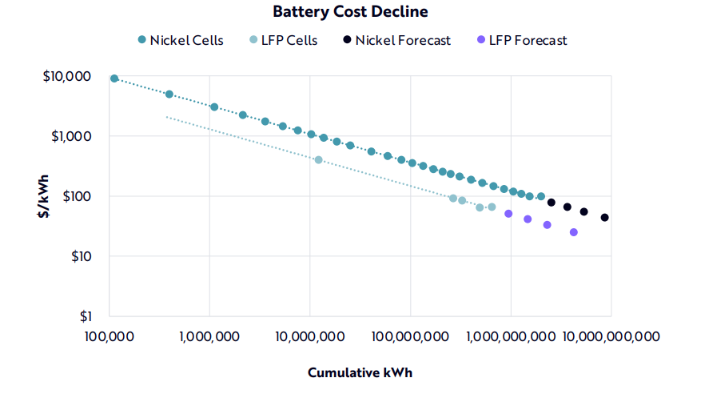

The importance of cost reduction in the field of electric forklifts: Electric forklift manufacturers are also facing cost issues, especially as market competition intensifies. The unit profit cycle is compressed downward, which shows the urgency of reducing manufacturing costs for the electric forklift industry.

Challenges in the new energy vehicle market: Similar to the new energy vehicle market, the electric forklift market may also face some challenges, such as initial purchase cost and operating cost. This requires manufacturers to improve cost performance while reducing costs to meet market demand.

Opportunities and challenges in the energy storage battery market: Energy storage batteries are also used in the field of electric forklifts, especially in terms of large-scale energy storage needs. Reducing the cost of energy storage batteries can stimulate greater market demand, which is both a challenge and an opportunity, as the cost reduction will help electric forklift manufacturers provide more attractive solutions.

Applicability of Wright's Law to the electric forklift industry: Electric forklift manufacturers can also learn from the principles of Wright's Law, which is that product performance increases accompanied by cost reductions. This trend plays an important role in the continuous development of electric forklift technology and the expansion of the market.

In summary, electric forklift manufacturers can learn from cost reduction, performance improvement and market demand when pursuing more competitive solutions, similar to the new energy vehicle market. Reducing costs and improving performance can help drive sustainable development and market penetration of electric forklifts.

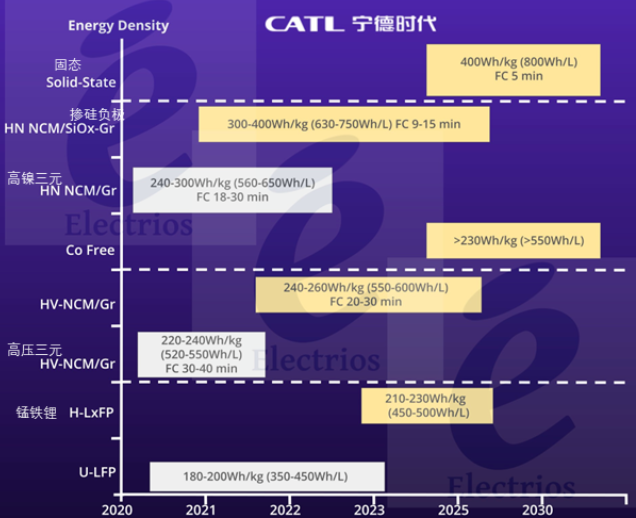

New lithium battery technologies are roughly divided into two types. One is the material system, which is the basis for a big jump in performance, and the other is structural innovation, which is a small iteration. The fast pace of structural innovation has been the main driving force for the improvement of the battery life of new energy vehicles in recent years. There are also endless fancy names, such as CTP, long and short blades, one-stop, Rubik's cube, and magazine. Material innovation takes ten years to develop, and the pace of progress is often slower than investors expect.

On the one hand, material innovation is a systematic project that requires multi-dimensional trade-offs. Both main materials and auxiliary materials affect the whole body, and the verification period can be as little as one year or as long as several years. In the marathon implementation process of new technologies, which link is the decisive step, and whoever plays a key role can obtain the most generous profits.

The characteristics and advantages of lithium batteries (lithium-ion batteries) make them widely used in a variety of applications, including forklifts.

High energy density: Lithium batteries have high energy density and can store a large amount of electrical energy in a relatively lightweight volume. This is particularly beneficial for applications that require long periods of operation, such as forklifts.

High discharge power: Lithium batteries can provide high discharge power and respond quickly to demand. This allows the forklift to quickly accelerate or brake when needed, improving operating efficiency.

Long cycle life: Lithium batteries generally have a long cycle life, can be charged and discharged multiple times, and are relatively stable. This helps reduce maintenance and battery replacement costs.

No memory effect: Lithium batteries have no memory effect, which means they can be charged at any state of charge without waiting to be completely depleted. This helps increase battery usage flexibility.

Environmentally Friendly: Lithium batteries have a lower environmental impact than some other types of batteries because they do not contain harmful heavy metals, such as lead-acid batteries.

Lower maintenance costs: Lithium batteries generally require less maintenance because they do not require regular additions of liquid electrolyte, like lead-acid batteries.

Fast Charging: Lithium batteries can accept a relatively quick charge, reducing downtime.

In the forklift world, these characteristics make lithium batteries a popular battery option because they help improve forklift performance, efficiency, and reliability. However, lithium batteries also require careful management and maintenance to ensure their long-term performance and safety.

Development history of the global lithium battery industry:

In the early 1990s, lithium batteries were first used in portable electronic products by Japan's Sony Corporation, marking the beginning of the commercial application of lithium batteries. With the popularity of electronic products such as smartphones, MP3 players, and tablet computers in the early 21st century, as well as the continuous improvement of lithium battery production technology, lithium battery production has grown rapidly, and the global lithium battery industry has entered a period of rapid development. In recent years, due to the rise of new energy vehicles, electric light vehicles, power tools, and energy storage, the global lithium battery market has maintained a rapid growth trend.

The development history of China's lithium battery industry:

China's lithium battery industry started relatively late. Since the first introduction of lithium battery-related technology in 1998, China's lithium battery industry has experienced 24 years of development. Under the active guidance of national policies and the independent innovation of domestic enterprises, China's lithium battery industry chain is increasingly improving, and the market size is expanding. A group of leading lithium battery companies with international competitiveness and leadership have emerged in China, forming a competitive landscape with traditional lithium battery producing countries such as Japan and South Korea.

China's lithium battery industry is emerging in the global market. It is not only an important country in the production of lithium battery products, but also has competitive advantages in fields such as new energy vehicles. China's lithium battery companies continue to grow and actively participate in international market competition, which has had an important impact on the development of the global lithium battery industry.

Applications of lithium batteries in forklifts:

Forklifts typically use power lithium batteries, which provide the power needed to propel the forklift to perform various tasks such as cargo handling and stacking. The application of power lithium batteries in forklifts is called forklift power batteries. These batteries are used in both large power batteries and small power batteries. This enables forklifts to gain advantages such as high energy density, fast charging, long cycle life and high discharge power, improving forklift performance and efficiency.

Future trends:

With the rise of electric forklifts: The electric forklift market is growing rapidly as concerns about environmental protection and energy efficiency increase. This will further promote the demand for forklift power lithium batteries, prompting the lithium battery industry to continuously improve technology, improve battery performance, and reduce costs.

Intelligent forklifts and energy management: In the future, forklifts will be more intelligent and equipped with advanced battery management systems to optimize energy utilization and extend battery life. This will help improve the efficiency and reliability of your forklifts.

Energy storage forklift: With the development of the energy storage field, forklifts may be used for peak shaving, valley filling, energy storage and other applications. The demand for energy storage lithium batteries will be driven in this area.

In summary, lithium batteries have broad application prospects in the field of forklifts and will continue to benefit from the rapid development trends of the lithium battery industry, including technological innovation and market demand in the fields of power, consumption and energy storage. The forklift industry will actively adopt lithium battery technology to improve its performance, efficiency and sustainability.

Lithium batteries are currently the most important application market for lithium batteries, mainly used in three fields: new energy vehicles, electric light vehicles, and power tools. On the policy side, under the macro-background of addressing climate change and promoting green development, new energy vehicles have become a recognized mainstream development direction with their obvious advantages in energy efficiency, environmental protection and intelligence. In October 2020, my country issued the "New Energy Vehicle Industry Development Plan (2021-2035)" to strongly support the development of the new energy vehicle industry and proposed that by 2025, my country's new energy vehicle sales will reach the total new automobile sales. By 2035, pure new energy vehicles will become the mainstream of new sales vehicles, and there is a grand vision to achieve full electrification of vehicles in the public sector.

On the technical side, after years of policy encouragement and corporate R&D innovation, the technical level of domestic power battery companies has continued to increase, laying the foundation for the long-term development of the lithium battery market for new energy vehicles in my country. In terms of international competitiveness, the market share of well-known companies such as CATL and BYD ranks among the top in the world, keeping pace with Japanese and Korean companies; in terms of continuous innovation, domestic lithium battery companies have successively launched new technologies such as CTP, blade batteries, and JTM, and their technical levels have continued to improve.

On the market side, new energy vehicle sales in 2022 will be 6.8866 million units, a year-on-year increase of 95.61%, and the annual penetration rate will increase from 13.4% in 2021 to 25.6%, realizing the "New Energy Vehicle Industry Development Plan (2021-2035)" ahead of schedule In 2025, the sales volume of new energy vehicles will reach the goal of reaching a penetration rate of 20%, moving towards the vision of "pure electric vehicles becoming the mainstream of new sales vehicles in 2035, and vehicles in the public sector becoming fully electrified".

Application of lithium batteries in forklifts: Power lithium batteries are currently the main application market for lithium batteries. Similar to new energy vehicles, electric light vehicles and power tools, forklifts also widely use power lithium batteries to provide efficient electric drive. This helps improve forklift performance, reduce maintenance costs and promote electrification of forklifts.

Policy support and grand vision: The government supports the development of new energy vehicles in the macro context of combating climate change and promoting green development. Similarly, the forklift industry has also benefited from policy support to reduce emissions and achieve full electrification. The Chinese government has put forward an ambitious vision, requiring vehicles in the public sector to be fully electrified, which will also affect the forklift field and promote its development in a more environmentally friendly direction.

Technological innovation and international competitiveness: The forklift industry can draw inspiration from the examples of domestic power battery companies’ continuous improvement in technology levels. Similar to CATL, BYD and other competitive companies in the international market, the forklift industry can continue to innovate, launch new technologies, and improve the performance of lithium batteries to meet growing demand.

Market growth and increased penetration: The growth and increased penetration of the new energy vehicle market indicates the popularity of the electrification trend, which also applies to the forklift industry. With the widespread adoption of electric forklifts, the forklift industry will see market growth and move towards the goal of full electrification to improve efficiency, reduce operating costs and meet environmental requirements.

In general, the successful application and rapid development trend of lithium batteries are not only applicable to the field of new energy vehicles, but also provide reference and inspiration for the forklift industry, helping the forklift industry to make important progress in electrification and sustainability.

① The overall industry competition pattern of cylindrical lithium battery manufacturers

According to the "China Cylindrical Lithium-Ion Battery Industry Development White Paper (2022)" released by EVTank, the global cylindrical lithium battery industry is relatively highly concentrated, with the top nine cylindrical lithium battery manufacturers accounting for approximately two-thirds of the market share, ranking high The manufacturers are Panasonic Group, LG Chem, Samsung SDI, Yiwei Lithium Energy, Tianpeng Power, BAK Battery, Sunpower, Lishen Battery, and Highstar.

② Industry competition landscape of lithium battery manufacturers in each segmented application field

From the perspective of regional distribution, after years of policy encouragement, my country's lithium battery industry has developed rapidly. Major foreign lithium battery manufacturers such as Panasonic, LG Chem, and Samsung SDI have production bases in my country. At present, China has become the world's most important lithium battery manufacturer. One of the places of origin.

From the perspective of market segments, there are differences in the leading companies in each application field of power lithium batteries, consumer lithium batteries, and energy storage lithium batteries, but the overall situation is almost an oligopoly. The detailed competitive landscape of each segment is as follows:

a. Automotive power battery field

In the field of automotive power lithium batteries, domestic companies are in a relatively leading position in the field of automotive power lithium batteries, and the oligopoly pattern of leading companies in China, Japan and South Korea has basically formed. According to statistics, in 2021, the Chinese-funded company CATL, the Korean company LG Chem, the Japanese-owned company Panasonic, the Chinese-funded company BYD and the Korean company SKI respectively occupy the top five power battery installed capacity. The total market share of the top five companies is approximately 80%, a relatively stable oligopoly pattern has been formed.

b. Electric light vehicle power lithium battery field

In terms of lithium batteries for electric light vehicles (mainly electric two-wheeled vehicles), EVTank data shows that the production of lithium-ion two-wheeled vehicles in 2021 will be 13.17 million units, with an overall penetration rate of 24.2%, driving the output of lithium-ion batteries for electric two-wheeled vehicles. The goods amounted to 13.1GWh. From the perspective of the competitive landscape, according to the "China Electric Two-wheeled Vehicle Industry Development White Paper (2022)" released by EVTank, the major domestic electric two-wheeled vehicle lithium battery enterprise suppliers in 2021 are Phylion Power, Tianneng, and Xinneng Anhe Chaowei Battery, the four companies have a combined share of more than 70%. In addition, competing manufacturers in this industry include CATL, Far Eastern Electric, Hengdian DMC, BAK Battery, Yiwei Lithium Energy, Penghui Energy, Lishen Battery, etc.

c. Power tool power lithium battery field

In terms of lithium batteries for power tools, according to data from EVTank and Ivey Economic Research Institute, global power tool shipments and market size are expected to be 510 million units and 57.19 billion US dollars respectively in 2022. It is expected that by 2026, global power tool shipments will With more than 700 million units, the market size will exceed US$80 billion. Driven by the growth of the global power tool market, the global demand for lithium batteries for power tools is expected to exceed 4 billion in 2026.

From the perspective of competition, international lithium battery manufacturers started early and occupied a large market space: in 2017, Samsung SDI, LG Chem, and Murata occupied about 75% of the market share in the field of power tool batteries. Since 2018, under the background of continuous breakthroughs in domestic high-rate lithium battery technology and international lithium battery manufacturers focusing on the automotive power battery field, many domestic lithium battery companies such as Yiwei Lithium Energy, Lishen Battery, BAK Battery, and Tianpeng Power Supply have The battery suppliers have passed the certification of one or more well-known power tool manufacturers such as TTI, Bosch, Stanley Black & Decker, and Bosdal, and have entered the supply chain of international power tool manufacturers, gradually replacing the share of foreign battery manufacturers. According to EVTank data, in terms of the penetration rate of all-lithium battery two-wheelers in 2021, the "new national standard" and the entry of well-known companies will be long-term help in accelerating the replacement of lead-acid batteries by lithium batteries.

Characteristics of lithium battery industry

① Lithium battery safety issues need to be resolved urgently

Under the background that new energy vehicles are basically replacing traditional fuel vehicles, lithium batteries are currently the main power batteries used in electric vehicles due to their advantages such as high energy density, high discharge power, and long cycle life. However, in recent years, safety accidents caused by thermal runaway of lithium batteries have occasionally occurred, posing a threat to consumers' lives and property safety.

In order to deal with the safety issues of lithium batteries and promote the healthy development of strategic emerging industries such as new energy vehicles in my country, my country has announced the mandatory national standard "Safety Requirements for Power Batteries for Electric Vehicles". This standard will be implemented from 2021 and will mandate lithium batteries to leave the factory. Rigorous safety tests are conducted beforehand, including 6 safety tests on the battery cells and 15 safety tests on the battery system, to ensure the safety of lithium batteries.

With the implementation of mandatory standards, the safety threshold of lithium batteries has been significantly improved. The degree of battery safety guarantee will be increasingly valued by manufacturing companies, end users and government regulatory authorities. How will lithium battery companies minimize the risk of lithium batteries? Safety issues are challenges faced by lithium batteries and related industries.

② Multiple technical routes for lithium batteries coexist

In recent years, the commercial application of lithium batteries has developed rapidly. In order to cope with the increasing requirements for lithium batteries in terminal application markets such as new energy vehicles, emerging lithium battery technologies continue to emerge, showing the coexistence of multiple technical routes. At present, the differences in the technical routes of lithium batteries are mainly reflected in the cathode material system and packaging form.

First, there are differences in the technical routes of cathode materials for lithium batteries. Cathode materials are an important component of lithium batteries, and their characteristics have an important impact on the energy density, cycle life, safety performance, etc. of the battery. The technical routes mainly include ternary materials, lithium manganate, lithium iron phosphate, lithium cobalt oxide, etc. Battery precision structural parts and materials can be widely used as packaging or conductive materials for lithium batteries due to their strong versatility, and are generally not affected by the technical route of cathode materials.

Second, there are differences in the packaging forms of lithium batteries. Packaging form refers to the packaging structure of a single lithium battery. Different packaging forms require different processes and also correspond to different forms of battery precision structural parts. At present, the technical route of lithium battery packaging mainly includes three forms: cylindrical, square and soft package. At present, the three types of lithium batteries, cylindrical, prismatic and soft-packed, each have their own advantages and disadvantages. The global market has a competitive pattern of "three-thirds of the world", and all have large market development space.

In September 2020, Tesla launched a 46800 large cylindrical battery solution. Compared with traditional small cylindrical batteries, large cylindrical battery technology can reduce the number of batteries in the battery pack and the number of corresponding structural parts, increase energy density, and simplify battery management. System requirements are higher than prismatic batteries.

Judging from current progress, Tesla has achieved mass production of 4,680 large cylindrical batteries in 2022, with a weekly production capacity of 868,000 units, which approximately corresponds to the demand for 1,000 Model Ys. In September 2022, the BMW Group announced that it would use 46 series cylindrical batteries in its new models starting from 2025, and locked the first partners at CATL and Everview Lithium Energy. Other well-known battery manufacturers at home and abroad are also steadily advancing the layout of 4680 large cylindrical batteries.

The vigorous development and technological innovation of China's lithium battery industry have a profound impact on the electric forklift industry. Similar to the lithium battery field, the electric forklift market also needs long-term support to promote technological innovation and meet market demand.

China's lithium battery industry has experienced a development process from domestic breakthrough to world leadership to technology export. This also provides valuable experience in the field of electric forklifts. In the field of electric forklifts, technological output and innovation will help improve battery performance and reduce costs, thereby making electric forklifts more competitive.

In the past, the lithium battery industry has also been questioned during its rapid growth, which is somewhat similar to the development of the electric forklift market. In the electric forklift industry, we may also face market challenges and the need for technological innovation to respond to changing needs and environmental protection requirements.

In addition, China's lithium battery industry is looking forward to realizing "from Made in China to Created in China" in the field of solid-state batteries. Solid-state battery technology promises to deliver greater performance and reliability to electric forklifts while improving energy efficiency and reducing emissions.

In summary, the development experience and technological innovation spirit of China's lithium battery industry can be combined with the electric forklift field to promote the development of the electric forklift industry and meet future sustainability and environmental protection needs. This will help electric forklift manufacturers continue to improve product performance, reduce costs, and occupy an advantageous position in market competition.