Related News

Choose lithium battery for forklifts

There are increasing demands of advanced lithium battery for forklift industry recently, therefore we would suggest how to choose a right lithium battery for your forklifts!

CeMAT Asia Exhibition at Pudong Shanghai

CeMAT Asia Exhibition will be hold from 1st to 4th Nov 2016 at Pudong Shanghai

Wide Application of Lithium Iron Phosphate Batteries in Forklifts

2023-09-08 | Power Battery - Electric Forklift

What is lithium iron phosphate battery?

Lithium iron phosphate battery is a kind of lithium ion battery, which refers to a lithium ion battery using lithium iron phosphate as the positive electrode material. It is characterized by strong safety and stability, high temperature resistance and good cycle performance.

How long is the real life of lithium iron phosphate battery pack

The cycle life of long-life lead-acid batteries is about 300 times, and the highest is 500 times. The lithium iron phosphate power battery has a cycle life of more than 2000 times. Lead-acid batteries of the same quality are "new for half a year, old for half a year, and maintained for half a year", which is 1 to 1.5 years at most, while the lithium iron phosphate battery pack is used under the same conditions, and its theoretical life will reach 7 to 8 years.

Lithium iron phosphate battery packs are generally available for about 8 years; but if they are used in the south. The life of lithium iron phosphate battery is longer than 8 years. The theoretical life of the lithium iron phosphate battery pack also exceeds 2000 charge and discharge cycles, even if it is charged once a day, it can last for more than five years. Generally speaking, it is charged once every three days for daily household use, and it can be used for about eight years. However, due to the poor low-temperature performance of lithium iron phosphate batteries, the life of lithium iron phosphate batteries will be relatively longer in the southern region. Advantages of lithium iron phosphate battery pack compared with lead-acid battery

large capacity. Lithium battery cells can be made into 5Ah~1000Ah (1Ah=1000mAh), while lead-acid battery 2V cells are usually 100Ah~150Ah, and the variation range is small.

light weight. The volume of the lithium iron phosphate battery pack with the same capacity is 2/3 of the volume of the lead-acid battery, and the weight is 1/3 of the latter.

Strong fast charging capability. The starting current of the lithium iron phosphate battery pack can reach 2C, which can realize high-rate charging; the current requirement of the lead-acid battery is generally between 0.1C and 0.2C, which cannot achieve fast charging performance.

environmental protection. There is a large amount of heavy metal-lead in lead-acid batteries, which produces waste liquid, while lithium iron phosphate battery packs do not contain any heavy metals, and there is no pollution in production and use.

High cost performance. Although lead-acid batteries are cheaper than lithium iron phosphate batteries because of their cheaper materials, they are less economical than lithium iron phosphate batteries in terms of service life and daily maintenance. Practical application results show that the cost performance of lithium iron phosphate batteries is more than 4 times that of lead-acid batteries.

Lithium-ion battery refers to a secondary battery (rechargeable battery) that uses lithium as an energy carrier. When charging, lithium ions come out of the positive electrode, pass through the electrolyte and diaphragm, and are embedded in the negative electrode. The reverse process occurs when discharging, also known as rocking chair battery.

Lithium-ion batteries are divided into lithium iron phosphate batteries and ternary lithium batteries according to different cathode materials.

Lithium iron phosphate material is rich in production resources, and its cost, cycle life and thermal stability are superior to ternary materials. It is suitable for commercial vehicles, low-end passenger vehicles, energy storage and other fields. The theoretical specific capacity (energy density) of the ternary lithium battery is 60% higher than that of lithium iron phosphate, the charging rate is higher, and the low temperature performance is good, which is suitable for the fields of medium and high-end passenger cars.

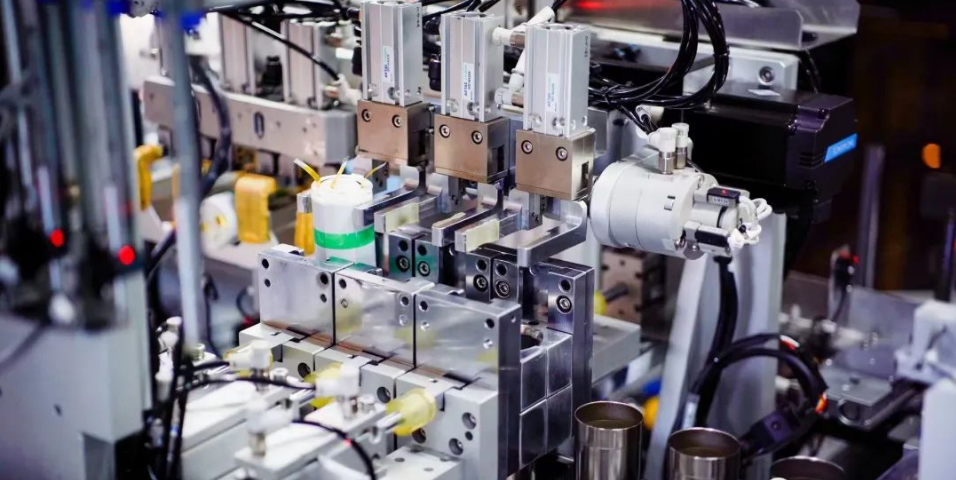

Lithium battery packaging process

Lithium-ion batteries are divided into square batteries, pouch batteries and cylindrical batteries according to different packaging processes.

The advantages of prismatic batteries are high packaging reliability, simple structure, high monomer energy density, high system group efficiency, and relatively good stability. System lifetime is lower than monomer lifetime.

Soft-pack batteries are packaged with aluminum-plastic film, which has the advantages of high energy density, small battery pack, and long cycle life. The disadvantage is that high-end aluminum-plastic film relies on imports, low production efficiency, and low yield.

Cylindrical battery hard-shell packaging has high reliability. The advantages are high battery consistency, mature technology, low cost, good battery product yield and heat dissipation performance, but the disadvantage is that the heat dissipation design after grouping is difficult and the system energy density is low. Low.

Power lithium battery technology route

Lithium iron phosphate power battery has regained its dominant position.

In the past three years, with the reduction of policy subsidies, the advantages of lithium iron phosphate in terms of cost and safety have gradually emerged. The installed capacity of the market has risen rapidly, and the market share has increased year by year. In 2021, the installed capacity of ternary batteries will be surpassed. The share of semi-power batteries increased to 55%.

The installed capacity of power batteries in China has maintained a high-speed growth trend, and the compound annual growth rate will reach 49% by 2025. Driven by the rapid growth of new energy vehicles in China, the installed capacity of power batteries in China will reach 110.1GWh in the first half of 2022, a year-on-year increase of 109.8%.

In terms of high specific energy, the energy density of a single ternary soft pack battery can reach up to 300Wh/kg. At present, the specific energy of a ternary square shell battery is close to 300Wh/kg, and the energy density of the system has reached 255Wh/kg. The energy density of the lithium iron phosphate blade (square) battery is close to 170Wh/kg, and the system energy density exceeds 140Wh/kg. The specific energy of the ternary soft pack battery has reached 300Wh/kg, and the energy density of the system has reached nearly 220Wh/kg.

The main technical direction of power lithium battery

In terms of high safety, at this stage, the safety performance of batteries is mainly improved by using three methods: body safety, process safety, and fire safety. The safety of the battery mainly depends on the modification and coating of non-flammable and non-flammable electrolytes, high-melting point separators and positive electrode materials to improve the safety of the battery itself.

In terms of long life, the service life of lithium iron phosphate batteries is generally higher than that of ternary batteries. The lithium iron phosphate blade battery has a service life of more than 5000 times, followed by the ternary soft pack battery with a service life of more than 3000 times, the square battery with a service life of more than 2000 times, and the cylindrical battery with a slightly lower service life of about 1000 times.

In terms of fast charging performance, the ternary battery rate is developing from the current 2C rate to 5C rate, and the charging time is shortened by 60%. Many companies are increasing the speed of ternary battery charging, and improving the battery's fast charging performance by increasing the charging voltage and the battery's high current tolerance. Energy storage lithium battery technology route

Large-scale energy storage is the main application scenario

China's energy storage battery shipments have maintained a high-speed growth trend, with an average annual growth rate of more than 50% in the next three years. In 2021, China's energy storage battery shipments will reach 48GWh, an increase of 167% year-on-year. It is estimated that the installed capacity will exceed 90GWh in 2022, an increase of 88% year-on-year, and will exceed 324GWh in 2025.

Domestic energy storage batteries are mainly used in large-scale energy storage (power system energy storage), communication system energy storage, household energy storage and portable energy storage. Large-scale energy storage is the main application scenario of energy storage batteries, mainly used for energy storage containerized systems on the power generation side, grid side and user side, accounting for 61% of shipments, followed by communication system energy storage, which is mainly used for communication Base station backup power accounts for 25%, and home energy storage products are mainly exported abroad. Portable energy storage accounted for the least, only 3%.

Many companies have entered the energy storage battery market with energy storage batteries

Energy storage batteries are in a stage of rapid development, and the market structure is uncertain. Ningde era came from behind with its strong cost control ability and scale advantages. At present, it has established extensive cooperation with State Grid, five major power generation groups, Kstar, Xingyun shares, Sungrow Power and other enterprises, temporarily ranking first; Household energy storage is expanding rapidly, ranking second in domestic shipments; BYD is deeply involved in the European and American markets, with solid customer and channel advantages, temporarily ranking third in China.

The development trend of energy storage battery products is product standardization, large-scale batteries, and de-modularization. Various companies are entering this industry and trying to become bigger and stronger. After 3 years, there will be a situation where the strong are always strong, and small and medium players who do not have the advantages of scale and the ability to develop and design high-performance batteries will be eliminated at an accelerated rate.

Lithium iron phosphate battery has become the mainstream route in China

Lithium battery performance requirements include energy density, power density, cost, life and safety. Energy storage applications have relaxed requirements on the energy density and power density of batteries, and more emphasis has been placed on reducing the cost of distribution and storage of electricity. Energy storage batteries must have low cost, long life, and ensure the safety of battery applications.

The performance of lithium iron phosphate batteries has a high degree of adaptation to energy storage needs, and has become the mainstream route in China.

Ternary lithium batteries have high energy density and power density, but are expensive and relatively weak in safety. In June 2022, "Twenty-five Key Requirements for Preventing Power Production Accidents (2022 Edition) (Draft for Comment)" issued by the Comprehensive Department of the National Energy Administration proposed that medium and large electrochemical energy storage power stations should not use ternary lithium batteries and sodium-sulfur batteries , It is not suitable to use cascade utilization power battery.

Lithium iron phosphate batteries have excellent safety, long cycle life, abundant metal resource reserves, low cost and environmental protection, and have become the main choice of energy storage batteries.

Development direction of large-scale energy storage technology

The installed capacity of large-scale energy storage is usually above the MWh level, and large batteries are expected to become the mainstream.

Large-scale energy storage system is an important facility to promote the large-scale application of renewable energy and build a new power system. It can play a role in peak regulation, frequency regulation, reserve capacity, smooth output, and ease grid congestion, including power generation side, grid side energy storage, etc. , usually dozens or even hundreds of MWh, the batteries used are mainly large-capacity square batteries.

In energy storage applications, large-capacity batteries of 280Ah and above can effectively reduce the cost of energy storage systems and reduce the difficulty of integration. They have obvious advantages and are gradually replacing the original 50Ah and 100Ah battery products in power storage scenarios.

The development trend of large batteries for electric energy storage is obvious. On the demand side, owners and investors of large-scale power storage facilities are paying more and more attention to 280Ah large batteries. Owners such as Huaneng and China Energy Construction all require a cell capacity of no less than 280Ah in their latest energy storage battery bidding.

On the supply side, since CATL launched 280Ah batteries in 2019, more than 10 domestic battery manufacturers have launched 280Ah battery products; battery manufacturers such as Haichen and Zhongxinhang have increased their production of 280Ah batteries.

Development direction of household storage technology

Household scenarios have relatively low requirements on battery energy density, and the main impact on user experience is the overall design of the product, including battery management and whole-house energy deployment. The requirements for battery performance are relatively relaxed, and the main emphasis is on safety and cost reduction.

The scale of the household energy storage system is at the level of 10kWh. Large cylindrical batteries (single capacity 10Ah-50Ah), square (50Ah-300Ah), and soft packs (30Ah-80Ah) are all selected by the company. At present, the battery packs used in household storage The route is not finalized.

Small batteries may become the mainstream of household storage. The current European household storage market is undergoing product iterations from low-voltage to high-voltage systems. The high-voltage platform can reduce the current, thereby controlling the heat generation of the system and improving the discharge efficiency. When the capacity of the energy storage system remains unchanged, the capacity of the battery cell corresponding to the high-voltage system decreases. For example, the low-voltage platform energy storage cells are mostly 100Ah, and the high-voltage platform gradually transitions to 50Ah. Small-capacity batteries below 100Ah still have a long application life cycle in the field of household storage. Key Technologies of Battery Materials

Top five battery materials

Positive electrode, negative electrode, electrolyte, lithium battery copper foil, and diaphragm are the main direct materials of lithium battery.

Cathode material is the most important material cost, accounting for about 55%. Lithium-ion batteries are mainly divided into lithium iron phosphate batteries and ternary batteries based on different positive electrode materials. Both power batteries are available, and energy storage batteries are almost all lithium iron phosphate batteries in China.

Anode materials account for about 14% of the total cost, including artificial graphite and natural graphite. Artificial graphite can be used in power batteries and energy storage batteries, while natural graphite is mostly used in consumer batteries.

The electrolyte accounts for about 13% of the total cost, and its main components are solutes, solvents and additives. Solutes, including LiPF6 and the new lithium salt LiFSI, are the main cost sources. Solvents are mainly cyclic carbonates and chain carbonates, including PC, EC, DMC, DEC, and EMC. Additives are mainly used for film formation, overcharge protection, low temperature resistance, flame retardancy, and increase in ratio. Common products include VC, FEC, PS, LiBOB, DTD, LiDFOB, etc.

Lithium battery copper foil is electrolytic copper foil, accounting for about 8% of the cost. Lithium battery copper foil is used for lithium battery negative electrode collector.

Diaphragms account for 4% of the total material cost and are divided into wet and dry diaphragms. The main cost of the wet diaphragm is PE, and the main component of the dry diaphragm is PP.

Lithium iron phosphate batteries have significant advantages in the field of electric forklifts. Electric forklifts often require high-performance batteries to provide power for a variety of industrial and logistical tasks.

1. Long life: Electric forklifts need frequent charge and discharge cycles in industrial environments. With its excellent cycle performance, lithium iron phosphate batteries can provide long-lasting service life in electric forklifts. This means that electric forklifts can operate efficiently for many years without requiring frequent battery changes.

2. Safety: In industrial places, the safety of electric forklifts is of paramount importance. Lithium iron phosphate batteries are known for their high level of safety and are not prone to overheating, burning or explosion. This ensures the stability and reliability of the electric forklift under various working conditions.

3. Fast charging capability: Electric forklifts often require frequent charging to maintain productivity. The lithium iron phosphate battery has a strong fast charging ability, which can complete the charging process faster, reducing the downtime of electric forklifts and improving production efficiency.

4. Environmental protection: In the industrial environment, environmental awareness is becoming more and more important. Compared with traditional lead-acid batteries, lithium iron phosphate batteries do not contain heavy metal lead, and have no pollution during production and use, which meets the sustainable development requirements of modern industry.

5. Cost-effective: Although the purchase cost of lithium iron phosphate battery is relatively high, it is usually more cost-effective in electric forklifts considering its long life, low maintenance cost and high performance. In the long run, electric forklifts may have a lower total cost of ownership.

In summary, lithium iron phosphate batteries are an ideal energy solution in the field of electric forklifts. It combines safety, performance, longevity and environmental protection, so that electric forklifts can operate more efficiently, reliably and sustainably in industrial environments. This is in line with Hande's demand for high-quality and sustainable electric industrial equipment such as electric forklifts.、